Vicon ROC RT 1000

Merger | Dry crop Merger

The only merger in the market that can operate with only one belt down while the others are in transport.

High-capacity rear-mounted three belt mergers with 10m working width inside delivery

The advantages of this Dry crop Merger

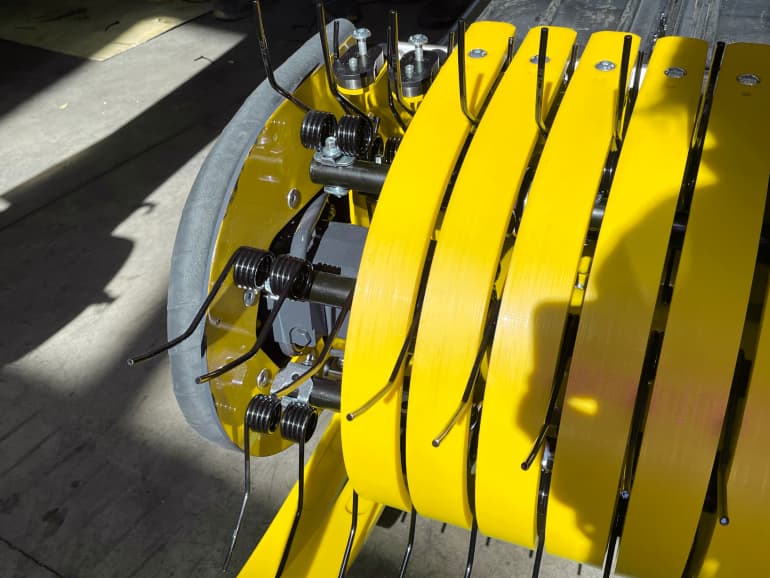

- The unique tine design and cam-controlled pick-up allow for clean raking of crops

- Reduced roping of hay and minor product loss

- The innovative belt design produces a smooth and fluffy swath

- The tractor requires only 100 hp, for low power consumption and better harvest time

Description

The continuous merger Vicon ROC RT 1000 is designed for professional use with a 10m working width and offers a revolutionary raking system with minimal power requirements.Operating the merger requires a 100-horsepower tractor. This results in optimised working hours, reduced power consumption during harvesting, and uniform, gentle swath production. The advanced pick-up system has advantages over traditional rakes. It reduces hay loss, improves silage quality, and uses six rows of springs to lift crops onto a conveyor belt.

With its 10 m working width, the Vicon ROC RT 1000 can form swaths even after the harvested crop. It's the only merger that can be partially or completely folded, making it suitable for smaller working widths due to crop volume requirements or when an existing swath is present.

Highlights

- High capacity, rear mounted 3 belt merger with 10m working width - side delivery.

- Unique Pick-up system with 6 bars to ensure perfect ground adaption and clean merging.

- A 250 mm roller near the tines guarantees smooth material flow for best swathing, even in short crops.

- Partially or fully folding allows for raking smaller swaths or turning an existing one.

- Electric height adjustment system

- High steering and manoeuvrability

- Unique hydropneumatic road suspension system for fast and stable road transport

- Easy maintenance, quality, and replacement of components.

- An intuitive control unit operates all important functions

Features

Features

- A 10m working width, also ideal for forming swaths on an area where the crop has already been picked up

- The only merger in the market allowing to work partly or completely folded in case an existing swath needs to be turned or a smaller working width is due to crop volume required

- A three belt system with three pick-ups

- Fiberglass-reinforced saw blade-shaped crossbars provide optimal transportation for dry and wet crops

- An actively-driven belt, equipped with a sprocket and gear belt, ensures continuous operation even in heavy crop conditions

- Most maintenance and repairs can be done without removing the belt, and all parts can be disassembled with a single wrench

- The speed of the belt and pick-up can be precisely adjusted

- The tension of the belt is evenly distributed between the left and right sides since it is adjusted centrally

- Controlled pick-up with two cams and six tine bars

- For heavy crops such as silage and maize straw, it is recommended to use wide stripes

- Heavy-duty plastic strippers maintain shape when hitting rocks and their design prevents crop loss

- Even the shortest crop can be transported on the belt with the hydraulic adjustable roller suspended in all independent positions

- Replacing tines with only two bolts to remove (one per tine and one per plastic stripper) using only one hand

- It is possible to repair bearings, cam track, and tine bars without the need to disassemble the pick-up

- Electric height adjustment

- Our mergers are designed and built to be maintenance-friendly

- All components can be easily disassembled

- Wear parts are in small size and replaceable with limited efforts

- To ensure a high speed and a clean crop in all conditions, four suspensions are used

- The pickup's standard tandem wheels protect the ground from damage

- The tandem wheel comes equipped with a spring suspension system

- The machine has a transport width of 3m, which allows it to fit on all roads

- It is the only machine on the market that can operate with one belt down while the other is in the transport position

- An easy-to-use control panel manages all essential functions

- The terminal provides optional features such as belt auto-stop when lifting the machine to ensure a clean swath ending

Technical specifications

Download brochure| Vicon ROC RT 1000 | ||

|---|---|---|

| Working width (m) | 10.0 | |

| Pick up width (m) | 8.9 | |

| Transport width (m) | 3.0 | |

| Belts n. | 3 | |

| Power requirement (hp) | 90 | |

| Weight (kg) | 4980 |

Technical specifications

Technical specifications

Download brochureModel name |

Working width (m) |

Pick-up width (m) |

Transport width(m) |

Belts n. |

Power requirement (hp) |

Weight (kg) |

Vicon ROC RT 1000 |

10.0 |

8.9 |

3.0 |

3 |

90 |

5200 |

Vicon ROC RT 1150 |

11.5 |

10.2 |

3.0 |

3 |

100 |

5395 |