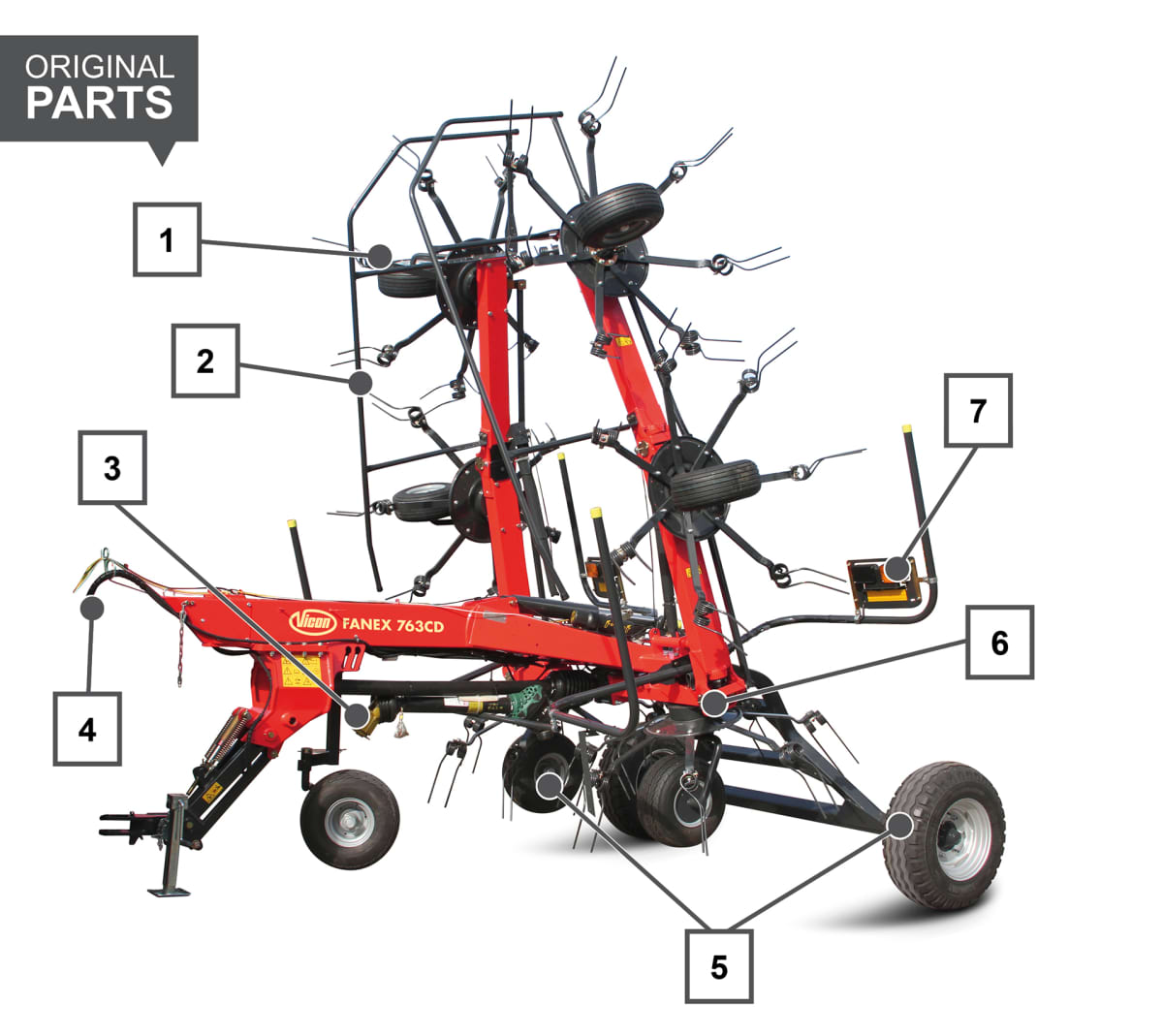

Tedder: GET READY FOR NEXT SEASON

Helpful tips and tricks to get your Tedder prepared to operate at it’s maximum capacity through the season.

Vicon Tedders are known for being low maintenance. However being prepared for the coming season by giving your machine a preseason health check will ensure top performance whilst keeping downtime to a minimum.

Check all Tines, safety fixings and Tine arms for wear or damage. Ensure all fixings are tight. Replace if necessary

Ensure all safety guarding is fitted and functions correctly.

Make sure all PTO drive lines and joints are clean and lubricated.

Check all hydraulic hoses and connections. Replace if necessary.

Check the condition and pressures of all tyres. Replace or adjust if necessary.

Check all steering and pivots points. Greasing if necessary.

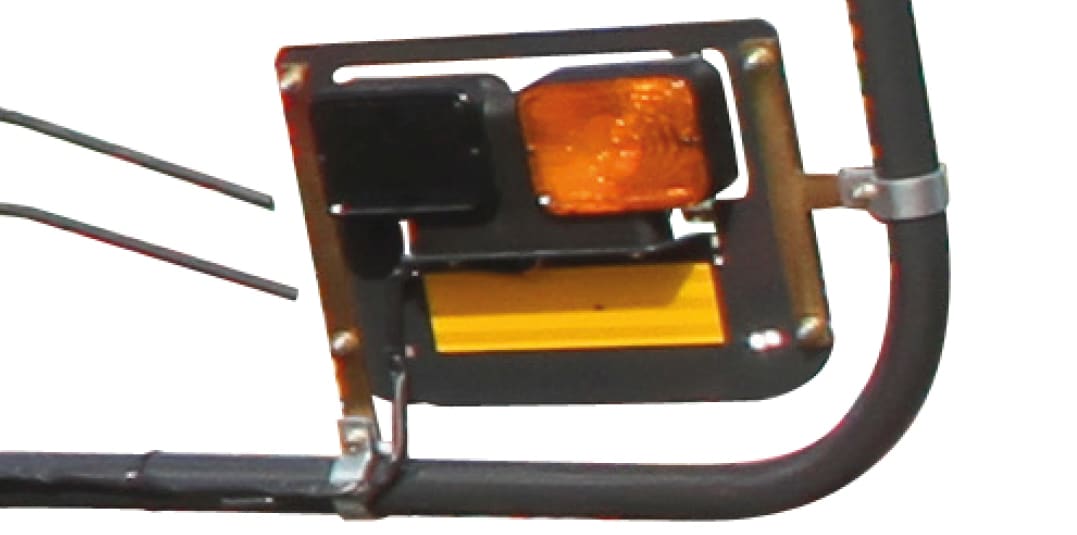

Check the condition and functionality of all Road lights. Repair/replace if necessary.

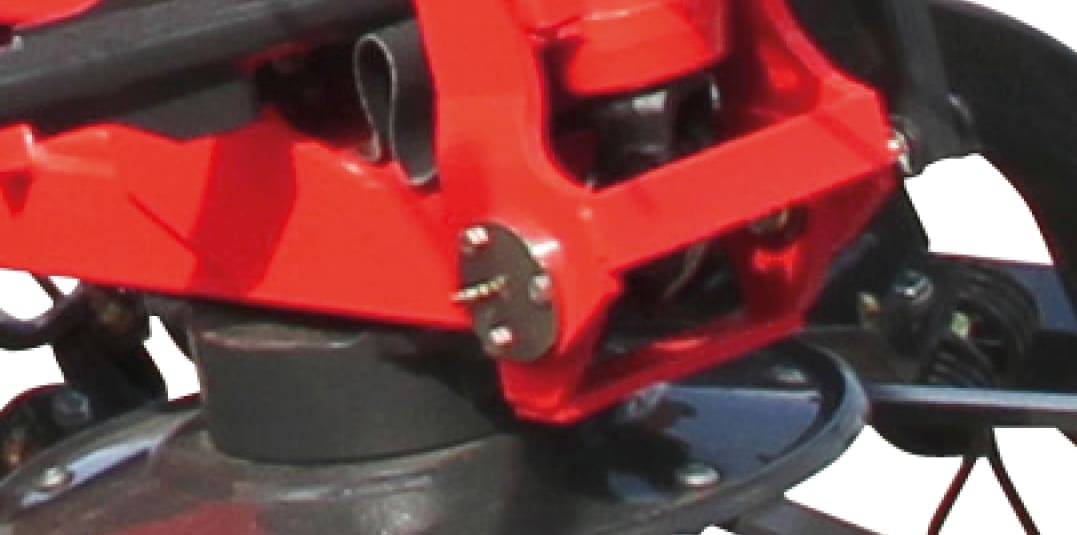

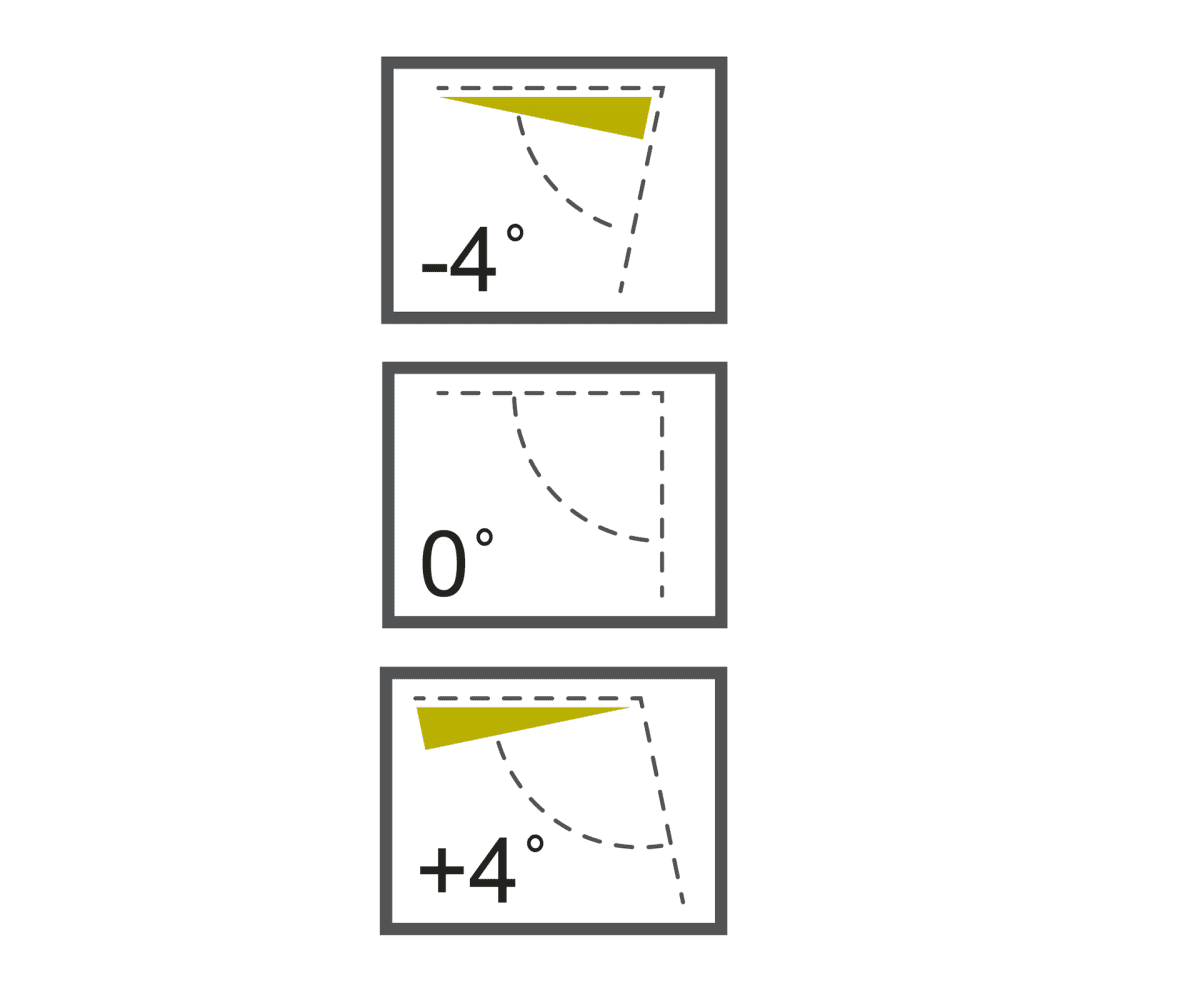

By inserting a triangular washer between the tine and the tine arm

– the Super-C tine can be locked in three alternative positions for optimum performance in different crop conditions.

Passive angle of -4°. Insert the washer with slope against the direction of rotation.

Standard angle of 0 degrees. No washer required as per standard factory specification.

Aggressive angle of +4°. Insert the washer with slope in direction of rotation.

The Super-C Tine is made from 10mm Shot-blasted Coil spring steel and has two equal length legs to evenly spread the load. Being 20% greater in diameter than conventional designs – results in one of the most durable and flexible tines on the market.

COMPACTLINE

VF16644530.86

PROLINE

VF16607564.86

PROLINE

VF16644761.86

PROLINE

A131393586

Damage to both livestock and machinery can be avoided by fitting Tine Safety clips to all tines. Mounted below the coil securing both tine legs - the safety device holds both halves of the tine together to prevent it from being lost in the crop.

COMPACTLINE

VF06580459

PROLINE

VF06565406

PROLINE

VF06565406

PROLINE

VF06565406

Using the appropriate Fixing Kits, securely tightened at all times, will ensure the tines give maximum performance and keeps losses and downtime to a minimum. (*Can be used with triangular washers)

COMPACTLINE

A131835630

PROLINE

VF06565744

PROLINE

A131835230

PROLINE

A131835430

Nothing is more frustrating that breaking down in the middle of a field – losing valuable time and productivity.

Keeping a Service Kit to hand, in the event of a breakdown, will ensure you are up and running in no time. The service kit contains sufficient fast wearing parts, ie tines, tine arms, tyres, tine fixing kit, tines savers etc that will get your machine back working in the event of a minor breakdown.

Ask your dealer to order a Service Kit for YOUR tedder and give yourself peace of mind when in the field.

A145581131

| ARTICLE NUMBER | MODEL | QTY |

| VF06564096 | Cpl. Wheel 16x6x8 TT 10PR Silver rim | 1 |

| VF16642644 | Cpl. Wheel 18.5x8.5-8 TT 6PR Silver rim | 1 |

| A131159786 | Tine arm | 2 |

| A131393586 | Spring tine, 10 mm, Tedder | 10 |

| A131835430 | Tine fixing set, Tedder (ProLine) Bent | 10 |

| A100020200 | Agraset 106 (3 x 8 pcs.) | 1 |

DISTRIBUTION CENTRE METZ - SERVICE 24/7

Time is money, and we know the importance of receiving the right parts at the right time! Your Vicon dealer is supported by a massive distribution network to supply you with exactly what you need, when you need it.

Our main distribution centre is located in Metz, France. A strategic location for distributing parts to all corners of the world. With over 70.000 parts in stock and 24/7 service, we are ready to supply you with parts – at any time!